WORLDWIDE

Product Line

Home > Product Line > EQUIPMENT FOR MAKING TIRES

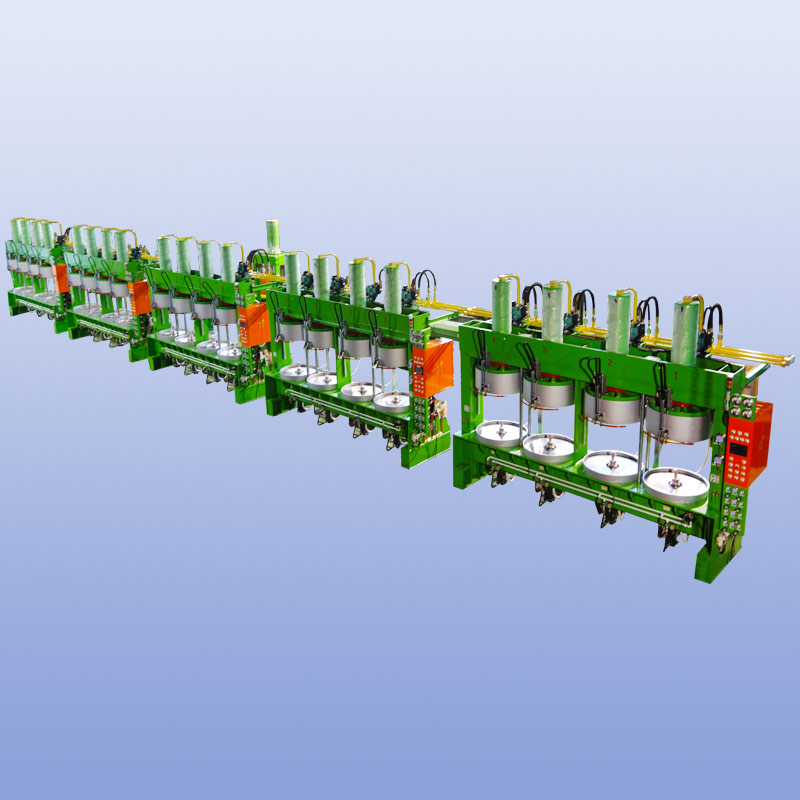

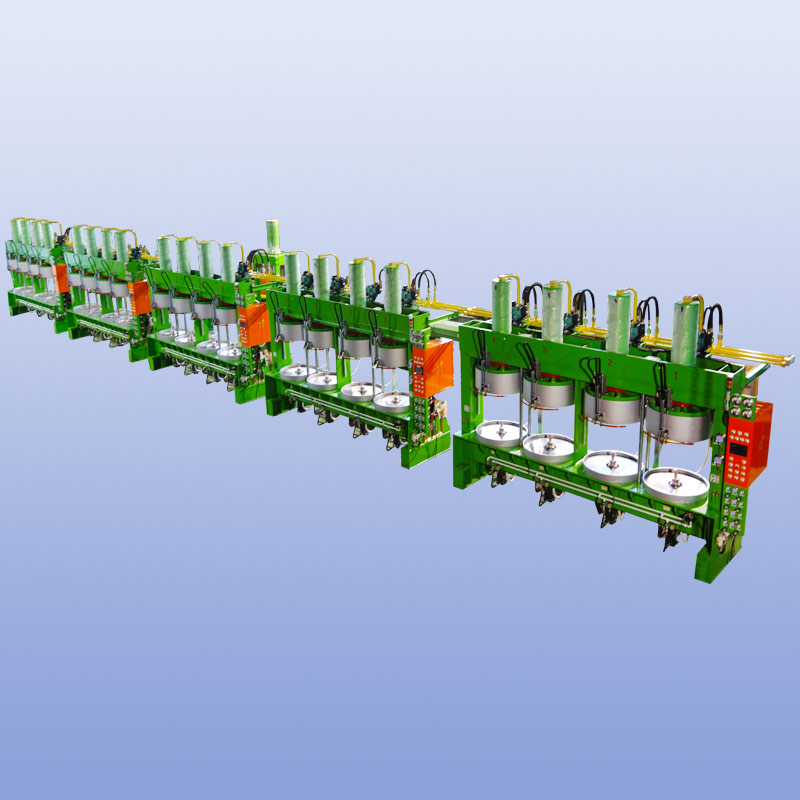

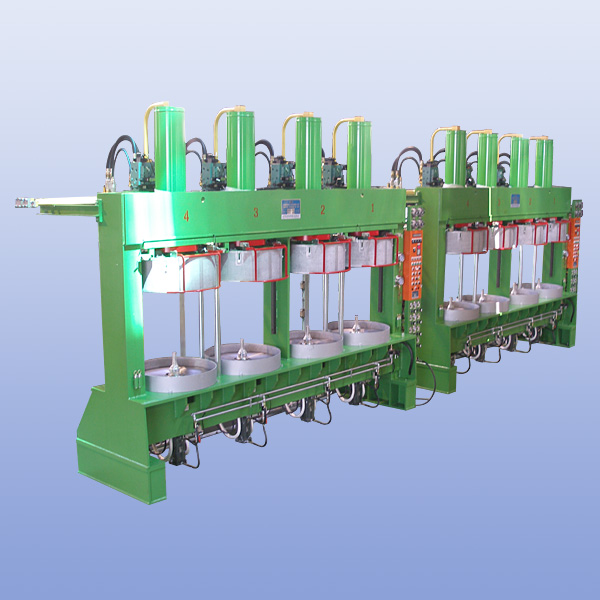

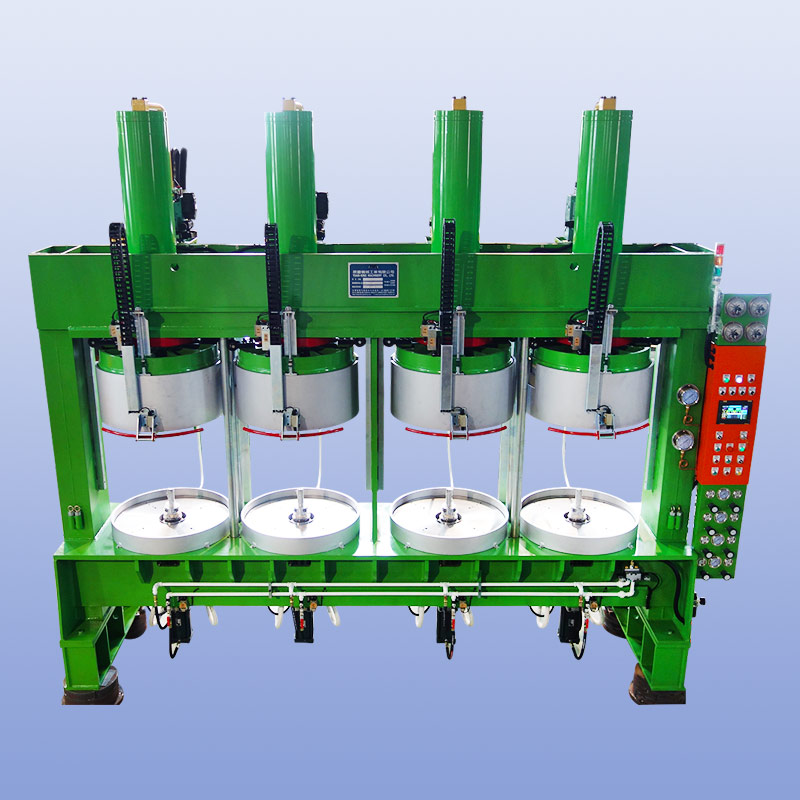

EQUIPMENT FOR MAKING TIRES

- Features

- Curing type could be selected in one or two cavities which has operation flexibility.

- Water cylinder with stainless steel material of bladder center mechanism. It has endurable corrosion and long life.

- Excellent heat conduction of platen, the temperature is evenly, no water accumulation.

- Fitting high quality gauges and valves. All products made in America or Japan which have long life and well driving efficiency.

- Hydraulic control unit by logic circuit controlled. it has large flow, fast speed of opening & closing mold, low noise, easy maintenance.

- The hydraulic power unit contains energy consumption saving controller, one unit serve for 5sets of hydraulic curing press.

- Electrical control system: auto cuing process with P.L.C control system along with HMI data record integration, it can display curing steps, curing time, internal & external pressure temperature. Such data would be saved in USB then move to computer for data analyzing for temperature variation during curing process. Further, curing conditions could be saved as recipe on HMI that is convenient call out from HMI while changing size in production, no need re-set curing condition every time.

- To enhance green tire shaped evenly by using secondary shaping which is able to reduce defective rate, improve tyre quality.

- All specification could be changed as customer’s requirement.

- Curing type could be selected in one or two cavities which has operation flexibility.

- Specification

MODEL HCP-24 HCP-28 HCP-30 HCP-32-(4M) TIRE SIZE I/D ; ATV I/D ; ATV ; M/C I/D ; ATV ; M/C I/D ; M/C ; ATV QUANTITY OF CRUING 4 PCS 4 PCS 4 PCS 2 PCS / 4PCS MAX CLAMP FORCE 53 TONS 80 TONS 103 TONS 103 TONS PLATEN DIA 600 M/M 710 M/M 760 M/M 815 M/M MOLD THICKNESS 100 M/M ~ 300 M/M 150 M/M ~ 350 M/M 150 M/M ~ 350 M/M 90 M/M ~ 200M/M