WORLDWIDE

Product Line

Home > Product Line > EQUIPMENT FOR MAKING TIRES

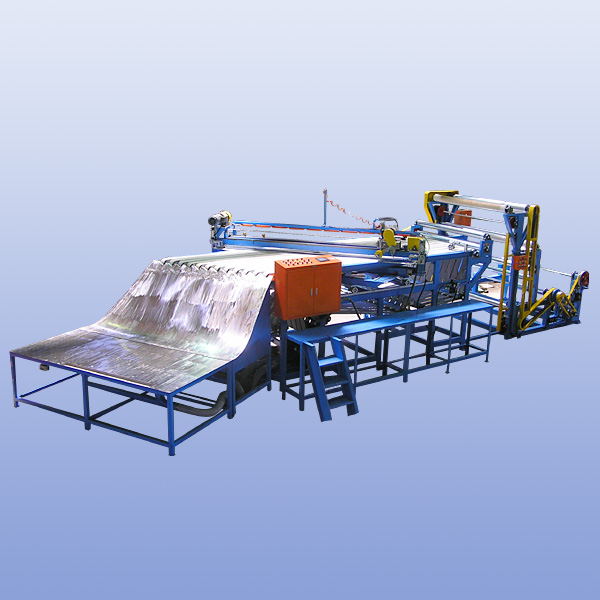

EQUIPMENT FOR MAKING TIRES

- Features

A. Main conveyor:

- Bias cutter mechanism welded with □square pipe, which has stable structure and good looking.

- With import commodity stick-proof material of multiple belt-conveyors match with elevated sliding framework which makes cut nylon cord slip smoothly.

- Special design of cutting traveler with steady motorization instead of air cylinder, avoiding oil pollution.

- Power sourcing of cutting traveler with safety electric rail, it has durable life. The cutting angle set on touch screen and adjusted with motorization, simple operation.

- Whole set traveler base is adjustable with front /rear movement by motorization in order to match nylon cord sliding position.

- Main transmission with servo motor drive, required length of nylon cord cut in high speed and precisely.

- Nylon cord and liner winding automatically and stably, nylon cord let-off tension is adjustable.

- Nylon cord and liner winder with safety chuck. It is easy and quick to change new fabric roll.

- Nylon cord and liner winding shaft drives by motorization and could be rotated in right and reverse.

- With auto detection for end of fabric, auto alarm and stop work.

- Each piece of banana roll in front and rear of festooner to prevent nylon cord wrinkled.

- Nylon cord sliding from stainless steel elevated frame to work table after cut.

- ylon cord jointed by worker and winded with wind up unit.

- Specification

MODEL BC-52 BC-60 SIZE OF TIRE For P/C-R ,passenger tire, bus & truck tire nylon cord cutting.

CUTTING ANGLE 45°~ 90° CORD WIDTH MAX 42 INCH MAX 60 INCH CUTTING SPEED EX: 18 ~ 22 PCS/MIN , 300 MM WIDTH CONVEYOR SPEED 45 M/MIN. CUTTING WIDTH 80 MM ~ 1,500 MM BED WIDTH 1,700 MM KNIFE GUIDE SLIDE BEARING CUTTING ANGLE ADJUST ELECTRICAL CUTTING WIDTH CONTROL AUTO COUNTER DIGITAL CONTROL